Moso 3D

MEDICAL Pack

3D printing for medical devices

With this 2 extruder + printing surface + tested materials you are going to be able to print with multiple materials, even if they have different requirements, because each material has its own extruder.

This “all included” MEDICAL Pack is a unique solution for your clinic or lab.

3 ways to use 3D printing on medicine

Pre-surgical planning models

3D printed based on CT scans. Real size 3D prints are used to explain the procedure to the patient, planning the surgery and training

Orthoses and Prostheses

Orthoses and prostheses help their wearers to achieve a better mobility. But every wearer has a different anatomy, usage and therapeutic needs. Customization is a key point that 3D printing solves easily.

Customized medical devices

3D printers make it possible to fabricate customized medical devices for particular surgeon practices and also could solve hospitalary maintenance printing spare parts for your equipment.

MEDICAL Pack includes:

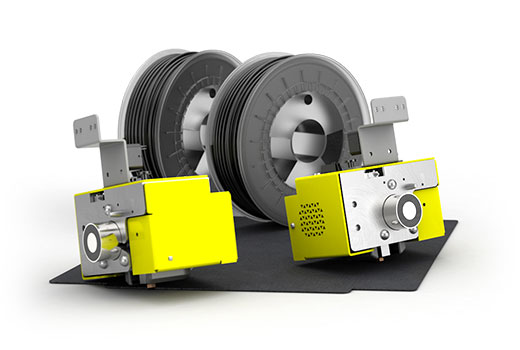

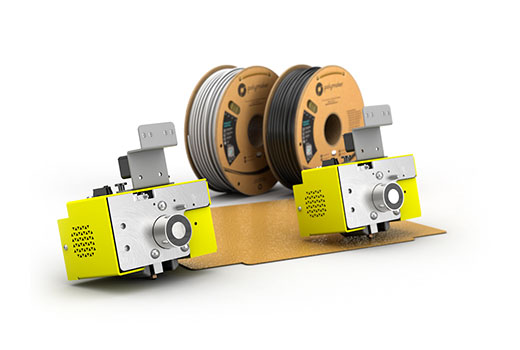

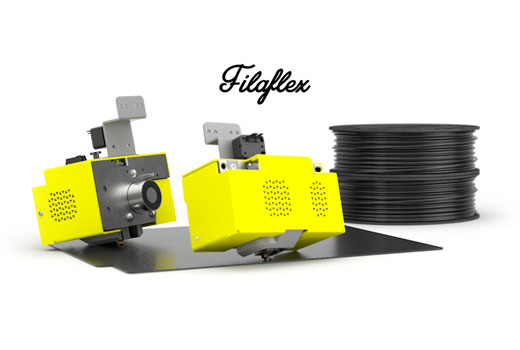

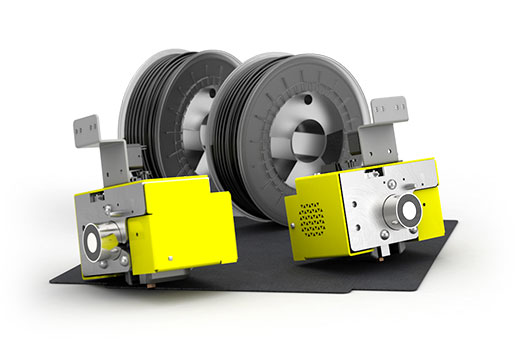

We provide you with all you need to start printing most materials, including custom printing profiles for our 3D printers, 2 filament spools with different properties, custom printing bed and detailed instructions on how to start printing. Using the provided extruders ONLY for those materials will keep your workflow flawless and with no other material contamination.

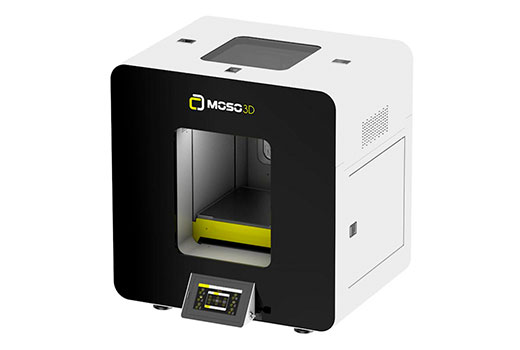

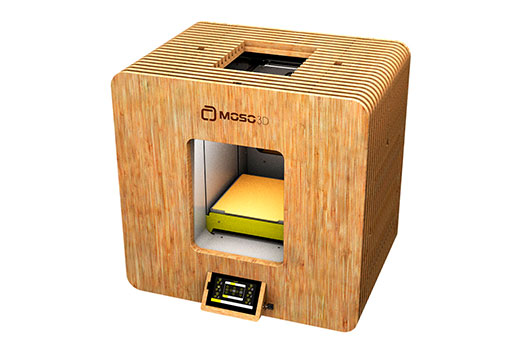

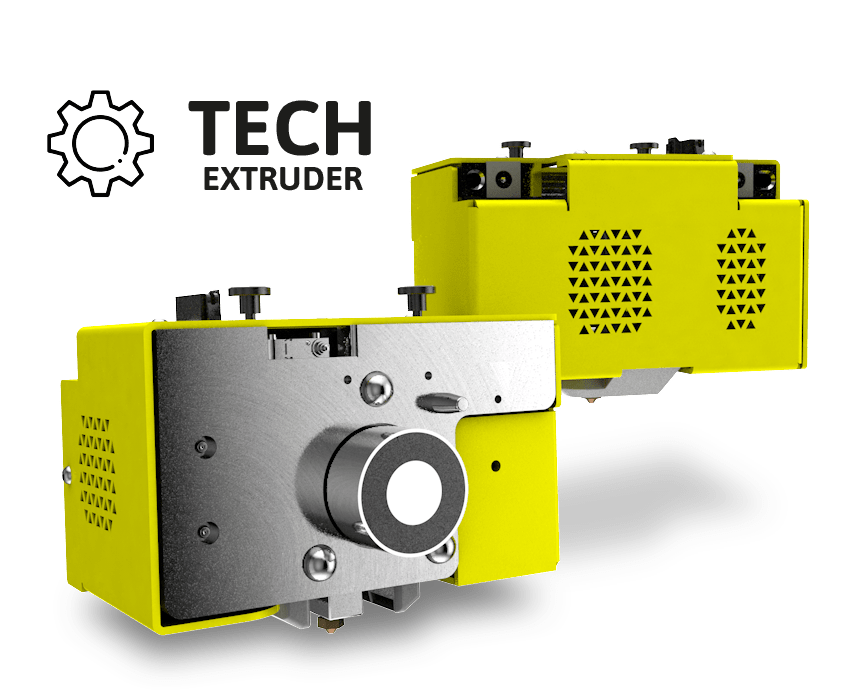

TECH X2

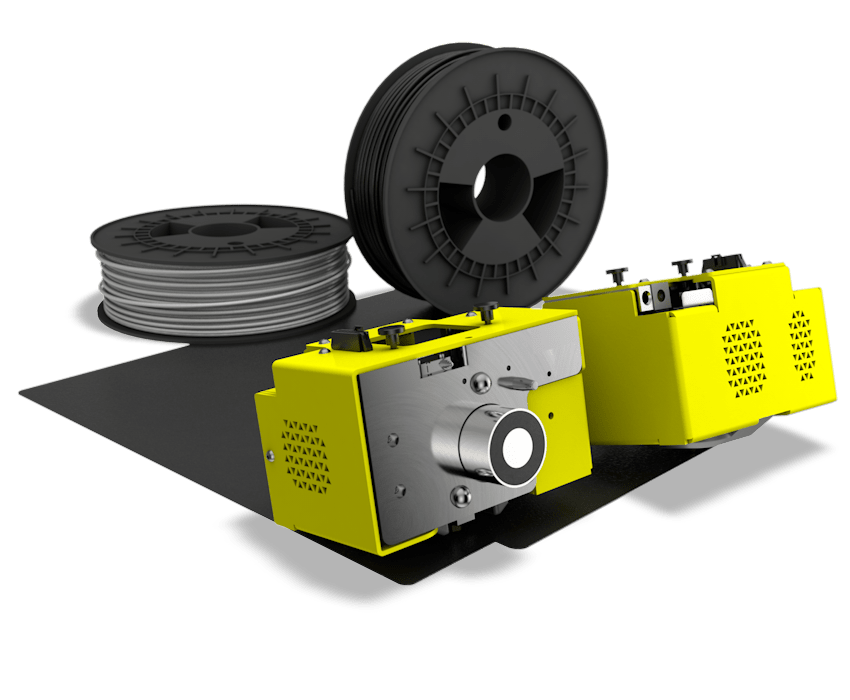

EXTRUDER

PC

Magnetic Bed

Elasto A

HealthFil

Structura MA

HealthFil

4 simultaneous material

3D printer for your medical purposes

Special Extruder for flexible filaments

Avoid the common printing issues with a custom designed extruder to print technical filaments easily.

-

Nozzle: 0.6 / 0.8 mm

-

Filament: 1,75 mm

-

Materials: Structura MA, Elasto MA

-

Temperature: Up to 280ºC

-

Nozzle material: Nickel plated copper

Structura MA

Structura MA was created to combine lightweight properties with mechanical strenght.

The addition of carbon fibers allows the production of structural supports with more advanced geometries and by overcoming more constructive challenges than ever before.

This material doesn’t produce chips when it broke, and it’s 100% skin contact approved

Structura MA

Structura MA was created to combine lightweight properties with mechanical strenght.

The addition of carbon fibers allows the production of structural supports with more advanced geometries and by overcoming more constructive challenges than ever before.

This material doesn’t produce chips when it broke, and it’s 100% skin contact approved

Complete Bundles

Talk to an Expert

Our team of application engineers and industry experts are here to help. We can answer any questions you have, ranging from details about our products to building an additive transformation roadmap for your business